Market independent

Flexible infrastructure that can be adapted to each workflow

AxionBlade® WMS can meet the needs of every type and size of organization, from a basic depot, to a complex warehouse including many operations and challenging processes . AxionBlade® WMS Warehouse Management System includes many modules and functional features helping you save time in the business process without distruption. System, materials, products, spare parts and so on. It is suitable to manage different warehouse management operations with different methods. Thanks to various embedded modules it is possible to perform many operations such as quality control, enumeration, pallet / package / product partition, transfer, label printing, reservation, return operations etc. in a controlled manner. As AxionBlade® WMS Warehouse Management System has an LP (License Plate) tracking infrastructure, you can monitor complete history of the product. With all these features, it provides excellent traceability in your warehouse.

The rate of capability without additional software development

Online and stable warehouse operations with mobile devices, mobility

Ability to adapt to different warehouse operations without the need for software development

Level of compatibility with current industry, hardware and software technologies

Developing according to special requests on a project basis

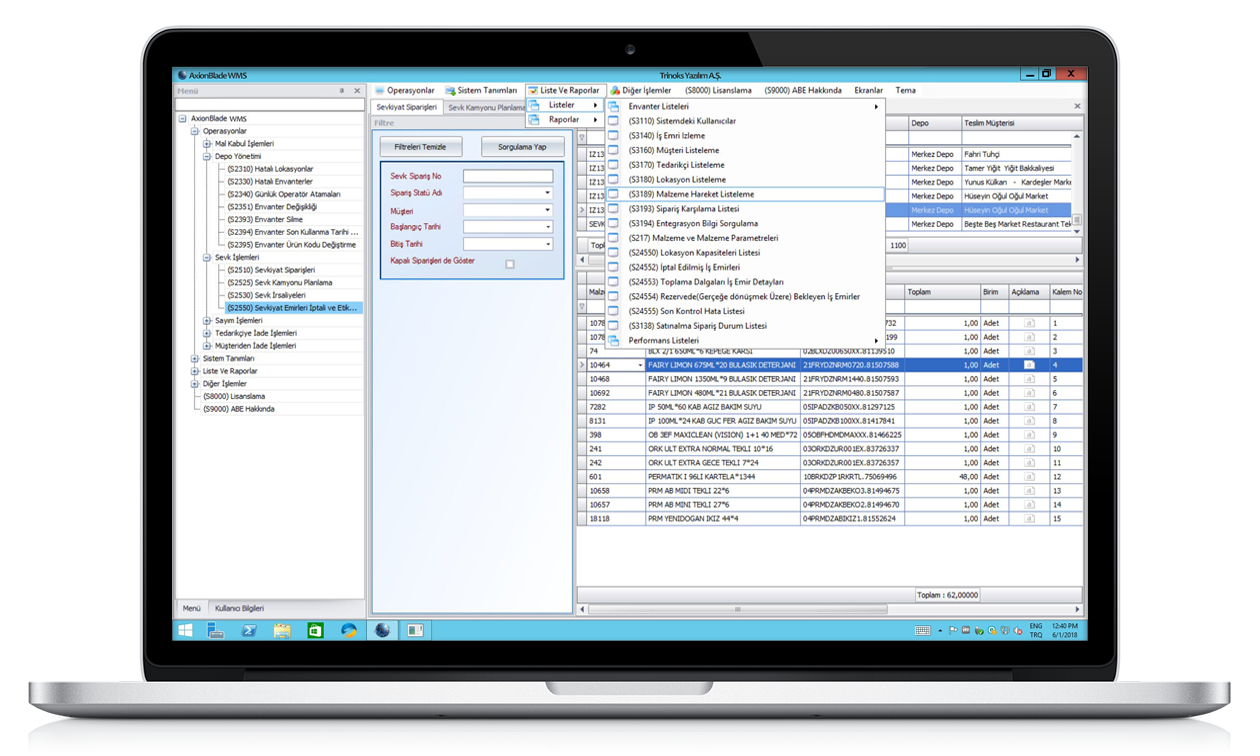

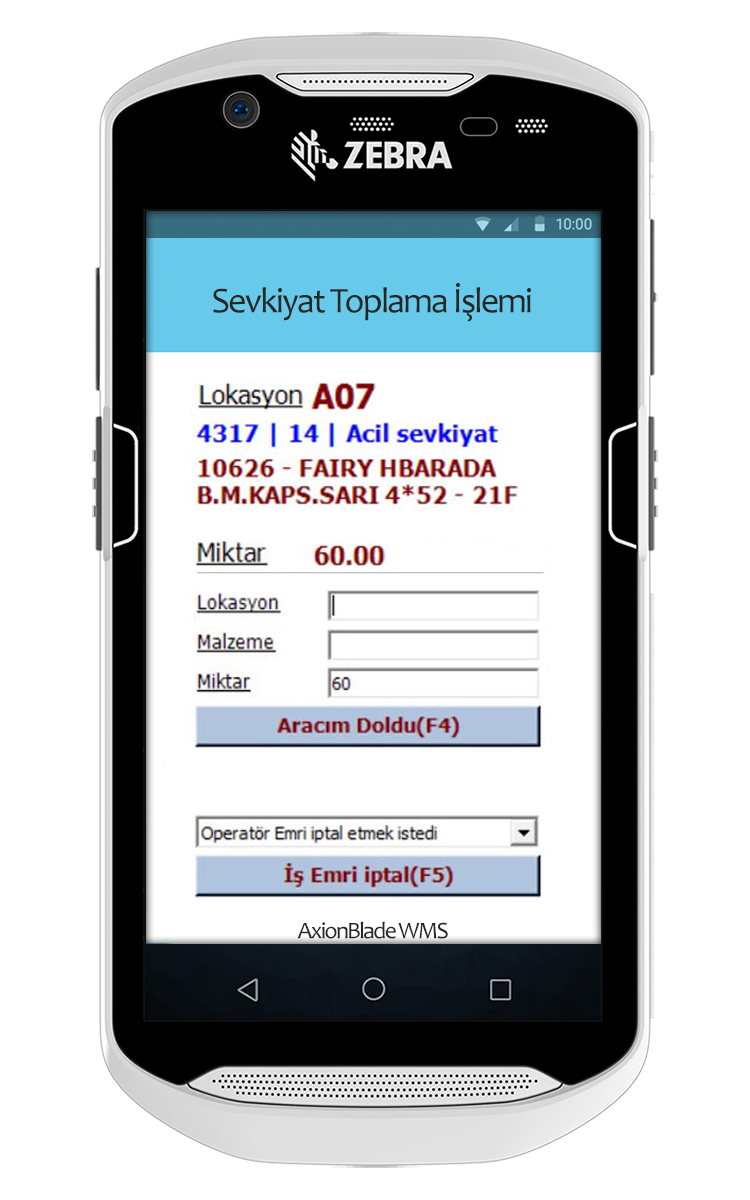

With the AxionBlade® WMS Warehouse Management System, you can carry out all of your warehouse processes with barcode or RFID control. The application is parametric by its development platform. It can be adapted to business of many different companies without code development. It has an order based working structure. Users authorized to make business plans create their plans through their computer screens and these plans are automatically or manually directed to the industrial mobile terminals used by operators working in the field. Operators use these terminals connected to the wireless network and execute the orders given by the system in a controlled manner. All transactions are recorded instantly and can be reported in detail. The AxionBlade® WMS Warehouse Management System has a rich report infrastructure for your shipments, goods acceptance, stocking, return and all other transactions. All of the list and report screens have an in-depth filtering feature, which allows you to generate different reports by applying multiple filtering on the same screen.

Furthermore, the Warehouse Management System allows you to access all data in order to help you measure the performance of the operators. LP (License Plate) for products allows you to get a full traceability report through Barcode Labels. AxionBlade® WMS Warehouse Management System features a platform for creating custom lists if you prefert to list data from the application instead of a report. Thanks to the "custom query lists" screen, system users can create their own queries and export the query product in 8 different formats such as Word, Excel, PDF etc. You can export all reports and lists you create on the AxionBlade® WMS Warehouse Management System in different formats or send e-mails directly.

Axionblade® WMS Warehouse Management System, is not only used within the borders of Turkey but in many neighboring countries such as Russia, Romania. It is a global software thanks to its multi-language platform. The system has a messaging platform and automatic e-mail feature, which allows you to get any desired data automatically at any time.

Ready for integration

Integration flexibility with various 3rd party software and automation systems

AxionBlade® WMS Warehouse Management System is capable of integrating with all the ERP software on the market. AxionBlade® WMS, which is already integrated with many software such as SAP, Oracle, Logo, Netsis, IFS, and Micro. Also it can easily be integrated with in-house software developed by the companies themselves.

In addition to this type of software, It has the ability to control and share instant information with many automation systems and equipment such as conveyor, sorting, routing, AGV, automatic feeding, robots etc. can be used in production areas.